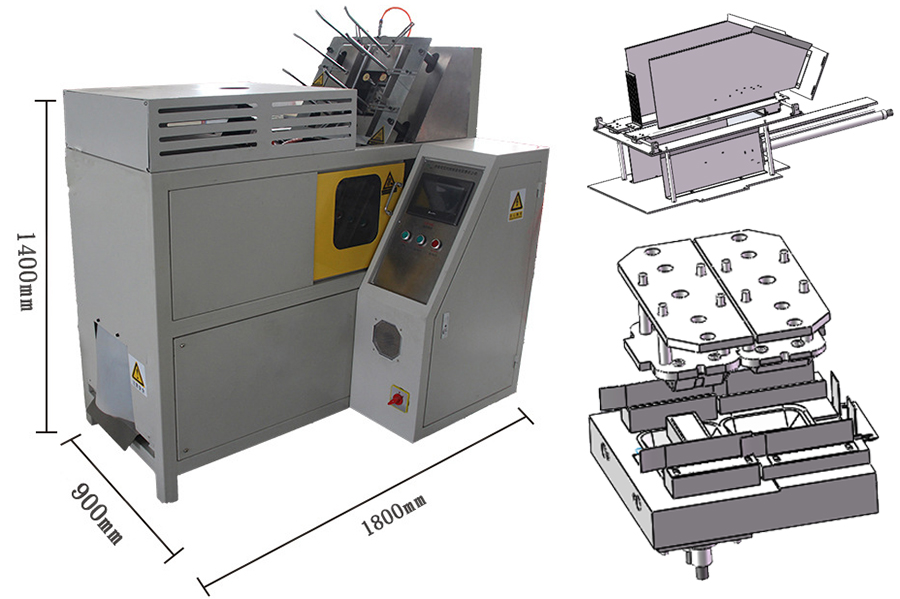

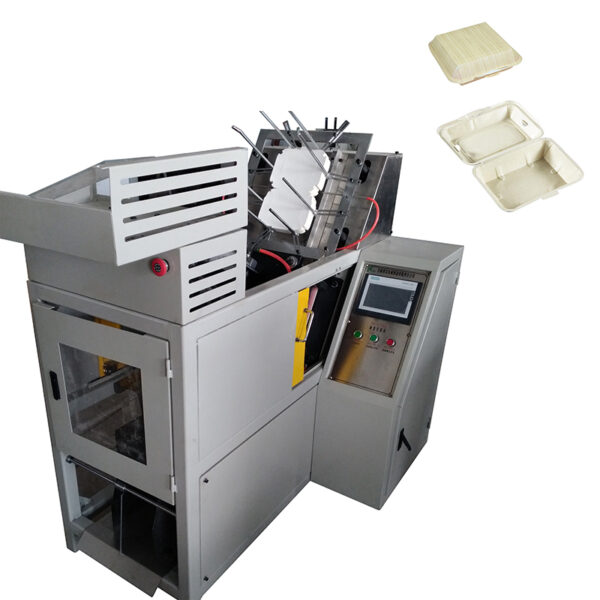

Disposable paper lunch box making machine

paper lunch box making machine is specially designed for disposable lunch box production. This machine is the latest developed by our factory. It does not require pipe cutting, pipe forming and hot melt adhesive. Fully automatic paper feeding and forming

Description

1. The oblique double cylinder lunch box machine has a one button start stop function, which is simple to operate and provides work efficiency. Customers can combine multiple machines into a production line according to actual needs.

2. This disposable paper lunch box machine is controlled by PLC, and the human-machine interface is a touch screen.

3. The machine is equipped with intelligent temperature control, which can automatically adjust the temperature according to the settings, making the performance more reliable.

4. The machine has a safety door design that can be opened and closed. When the safety door is opened, the machine will stop automatically. In any case, it can realize emergency stop, which improves the safety of the equipment.

5. When the machine breaks down, the display screen will display the fault content for easy maintenance.

6. Inclined double cylinder lunch box machine can realize one mold and two cavities, and the lunch box and the lid can be formed in one, and the automatic production can be realized.

Specification

| Power supply | AC220V/50HZ |

| Machine air supply | 0.6-0.8MPa |

| Equipment power | 0.8kW*4(number of heating rods) = 3.2 kw |

| Meal box size | Cover height ≤30mm, box height ≤50mm, width ≤320mm |

| Paper Type | Kraft coated paper, white card coated paper bamboo pulp coated paper, cup coated paper single-side coated paper |

| Production efficiency | 20-28pcs/min |

| Machine functions | PLC Control, touch screen operation display, one-key start, simple operation, automatic temperature control, automatic counting, automatic box collection fault shutdown, fault display |

| Machine dimensions | 1400*900*1800mm |

| Machine weight | 250kg |

| Safety protection | Safety cover, safety door switch, heat insulation protection, safety mark |