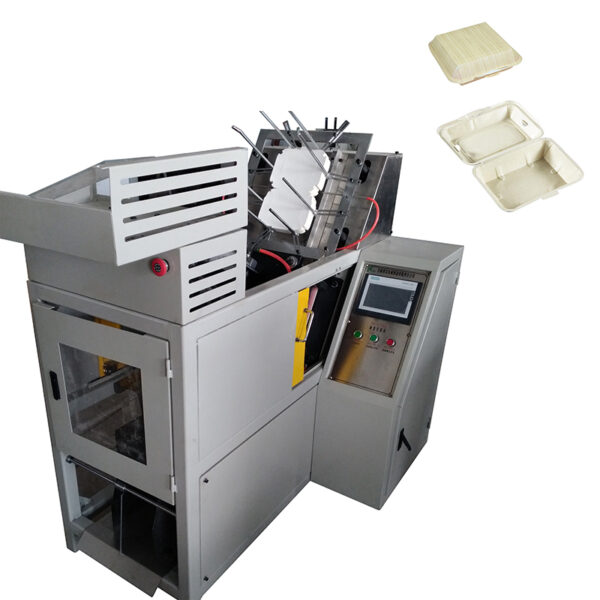

High-Quality Food-Grade Disposable Paper Salad Bowl Making Machine

High-Quality Food-Grade Disposable Paper Salad Bowl Making Machine

Description

Open Cam Paper bowl Machine improved on our hot sale XY-PB model machine, With advanced design and intelligent program, more reliable and durable, competitive price.

It makes both one-side or two-side PE-film-coated paper bowl after running a whole procedure of automatic Multi-step

pre-printed-bowl-fan-paper Feeding (Multi-step paper-feed and Anti-back device to keep the accurate position), cup-body-side

welding, silicone-oil lubricating(for top curling), robot transfer cup body, bottom-disk punching, bottom pre-heating and

pre-folding, main heating, bottom knurling(cool device for 2PE), top curling, paper bowl discharging and collecting.

|

Machine

|

Paper Bowl Making Machine

|

|

Weight

|

1700KG

|

|

Packing specification

|

2200*1230*1700mm

|

|

Raw Material

|

150-350gsm PE coated paper

|

|

Working Air Souree

|

0.4-0.5m3/min

|

|

Capacity

|

70-90pcs/min

|

|

Paper bowls specification

|

(A)φ40-100mm (B)φ40-140mm

|

Machine advantages:

# HMI & PLC Program control, easy operate, and intelligent,

# Step motor control the bottom feed, precision and reliable, one bowl fan cut one bottom disc, no wastage.

# Quality Open Cam (8-divide) drive, easy maintenance, stable and reliable, # Remote controller, easy control and adjustment,

# Quality Shaft & gears drive the movement, more stable than chain system, # Quality electric elements, long life, (DELTA,

Schneider, famous brand),

# Separately cam & rod, drive the knurling, curling, and heating parts, to keep machine stable and easy maintenance, # Working

power only 3.5KW, save cost (not include the air compressor power),

# Only ONE main turntable, more efficient and reliable. # Self lubricate (automatic oil lubricate),

# Robot straight lift the bowl body to main mold.

# Bottom disk straight punched and send to the bowl body, less wastage and precision. # Advanced bottom knurling system, reliable and long life,

# bowl side sealing by ultrasonic or ceramic hot air (suitable for 1PE & 2PE paper, available for light & heavy paper), # Bottom

heating by hot air, good sealing, (air compressor hot air or ceramic hot air),

# With bowl collector/stacker, One worker run 2~3 sets bowl machine, save labor